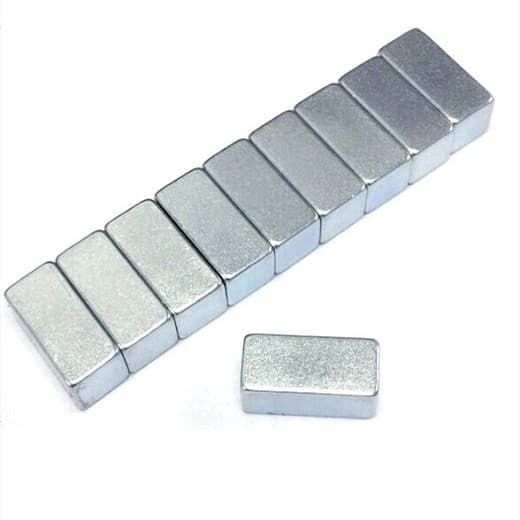

Sintered NdFeB Magnets

NdFeB magnets, also known as neodymium magnets, have very strong magnetic properties. NdFeB magnets are a type of rare earth permanent magnets and belong to permanent magnets. Another common rare earth magnet is samarium cobalt magnets.

Compared with other permanent magnet materials, sintered neodymium magnets have outstanding advantages in magnetic properties. It has extremely high magnetic energy product, coercive force and remanence. At the same time, it has excellent mechanical properties and is easy to process. These excellent properties make sintered NdFeB permanent magnets widely used in modern industry and electronic technology. It is widely used in permanent magnet motors, speakers, magnetic separators, computer disk drives, and magnetic resonance imaging equipment. In 2000, the total output value of rare earth permanent magnets exceeded that of ferrites for the first time. In 2010, the output value of sintered NdFeB permanent magnets exceeded that of ferrites, becoming the veritable “protagonist” of the permanent magnet industry.

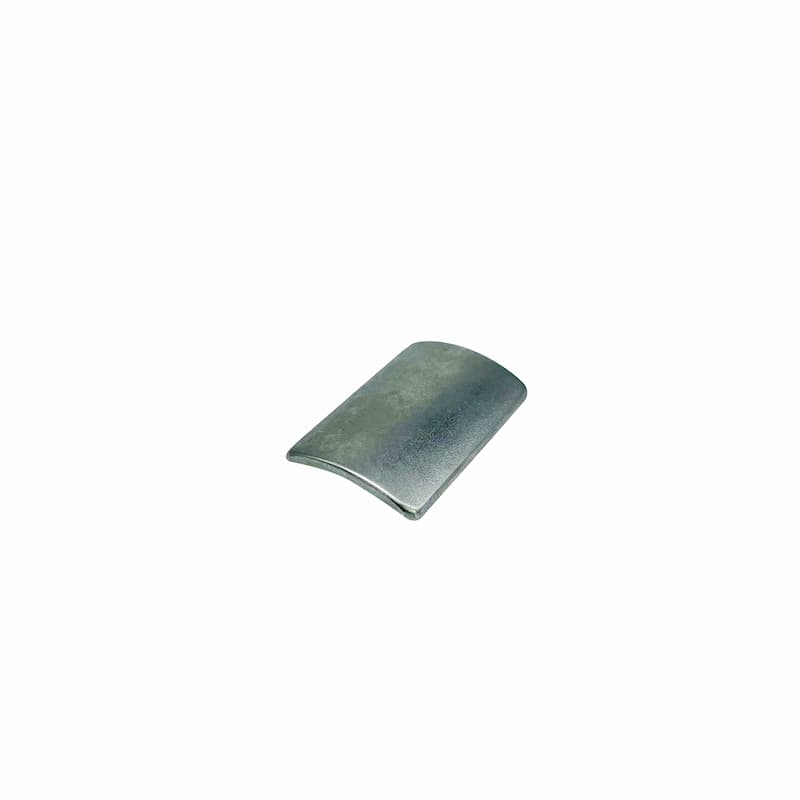

LD Magnet has been committed to the production and processing of NdFeB magnets for many years. We can not only produce NdFeB magnets of conventional shapes, but also customize NdFeB magnets of various unconventional shapes and sizes.