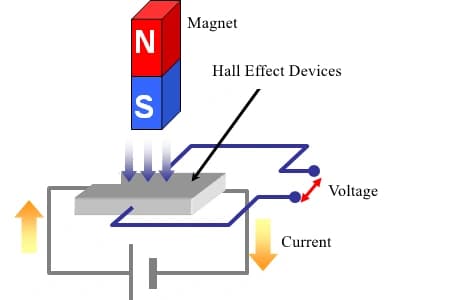

What is the principle of Hall effect?

The Hall effect describes how a conductor generates voltage when it carries an electric current in a magnetic field. Here’s how it works: Imagine you have a wire carrying an electric current. When you run a current through it, a current will flow through the wire. This current is made up of charged particles (electrons) moving through the wire. If you place a magnet near the wire (or place the wire in a magnetic field), the charged particles are pushed to one side of the wire by the magnetic field. When the charged particles gather on one side, there is a difference in charge at both ends of the wire, which creates a measurable voltage called the Hall voltage.

The Hall voltage can be measured, and its strength depends on factors like the strength of the magnetic field and the amount of current flowing through the wire. By measuring this voltage, we can determine things like the strength of the magnetic field or the speed of a rotating object.

The applications of hall effect sensors

Automotive Applications

Speed Sensors: Used to measure the rotational speed of wheels, crankshafts, or camshafts for engine control and anti-lock braking systems (ABS).

Position Sensors: For detecting the position of throttle valves, transmission gear shifts, and other moving components.

Door and Hood Sensors: To detect whether doors or hoods are open or closed for security and safety features.

Industrial Applications

Motor Control: Used in brushless DC motors to determine the rotor position, enabling efficient motor operation.

Current Sensing: Hall sensors can measure the current flowing through a conductor without direct electrical contact, enhancing safety and reliability.

Consumer Electronics

Smartphones and Tablets: Used to detect the position of flip cases or covers, turning the screen on or off as needed.

Keyboards: To detect key presses in non-mechanical keyboards.

Robotics

Position Feedback: Hall sensors provide feedback on the position of robotic arms or joints, helping with precision control.

Aerospace

Navigation and Control: Used in various applications for sensing and feedback in flight control systems.

Energy Management

Smart Meters: Employed in energy meters for measuring current and detecting overload conditions.

Medical Devices

Medical Imaging: Used in devices like MRI machines for precise positioning and movement detection.

Home Automation

Window and Door Sensors: For security systems to monitor whether windows and doors are closed or open.

SmCo Magnets for Vehicle ABS sensors

The above are the Samarium Cobalt magnets we produced. The N pole of each magnet is marked with a red dot to facilitate matching with the sensor.

How to select the right magnet to be used with Hall Effect Sensor?

Magnet Type

Common types include neodymium (NdFeB), Ferrite, and Samarium-Cobalt (SmCo). Neodymium magnets are strong and compact, making them a popular choice. SmCo magnets are playing an important role in some key areas.

Magnetic Field Strength

Gauss/Tesla Rating: Determine the required magnetic field strength at the Hall sensor’s location. Hall sensors are rated for sensitivity, so choose a magnet that produces a field strength within the sensor’s operating range.

Distance from Sensor

Air Gap: The strength of the magnetic field decreases with distance. Ensure the magnet is placed at an appropriate distance from the Hall sensor to maintain effective sensing capabilities. Consult the sensor’s datasheet for optimal distance recommendations.

Size and Shape of the Magnet

Geometry: The shape of the magnet affects how the magnetic field is distributed. For example, disc or cylinder shapes can provide a uniform field, while bar magnets may have more concentrated fields at the ends.

Size: Ensure the size of the magnet fits within the design constraints of your application while still producing the necessary field strength.

Magnet Orientation

Field Direction: Hall sensors detect magnetic fields perpendicular to the current flow. Ensure the magnet is oriented correctly to achieve the desired sensing action (e.g., north or south pole facing the sensor).

Temperature Stability

Operating Temperature Range: Select magnets that can withstand the operating temperatures of your application. Neodymium magnets can lose strength at high temperatures, be sure to pay attention to the working temperature.

Cost and Availability

Budget: Consider the cost of different types of magnets and their availability. Neodymium magnets tend to be more expensive but offer superior strength for size.

Magnetic Shielding

If your application involves potential interference from external magnetic fields, consider using magnetic shielding materials to ensure accurate readings.

Testing and Prototyping

Before finalizing your design, prototype the system using different magnet types and configurations to find the best combination for your specific needs. Measure the Hall voltage output at various distances and orientations to determine effectiveness.

By considering these factors, you can select the most appropriate magnets for your Hall effect sensor application, ensuring reliable and accurate performance. If you have a specific application or further questions in mind, feel free to ask us!