SMT (Surface Mounted Technology) is the most popular process in the current electronic assembly industry. It is used to install pinless or short-lead surface mount components (SMC/SMD, chip components) on the surface of printed circuit boards or other substrates, and solder and assemble them through reflow soldering or dip soldering. SMT has the characteristics of high assembly density, small size and light weight. After adopting SMT, the volume and weight of patch components are only about 1/10 of traditional plug-in components. Specifically, the volume is reduced by 40% to 60%, and the weight is reduced by 60% to 80%. This patch component has the characteristics of high reliability, strong shock resistance, low solder joint defect rate and good high-frequency characteristics, reducing electromagnetic and radio frequency interference.

In the processing of electronic PCB boards, magnetic fixtures are needed to support and position circuit boards and other devices. Compared with traditional furnace fixtures, magnetic furnace fixtures can be compatible with the functions of SMT printing, patch, reflow, water washing and other process fixtures, avoiding frequent disassembly of products, reducing operation procedures, and saving operation time. At the same time, magnetic jigs can reduce the number of jigs used in process operations, increase the versatility of jigs, reduce the production cost of jigs, and reduce the difficulty of automated operations.

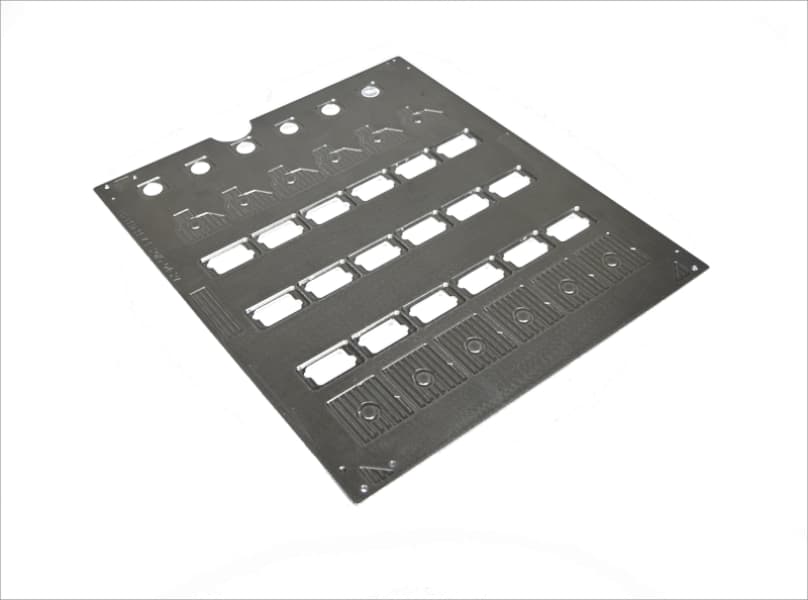

The magnetic furnace jig includes a buckle cover and a magnetic tray. The magnetic tray is a substrate inlaid with magnets, and the buckle cover is a metal sheet that can be attracted by the magnetic substrate. The buckle cover is provided with slots for printing solder paste and patches on the flexible circuit board, and the buckle cover has a steel sheet that can be attracted by magnets. Before printing, the magnetic tray is fixed on the positioning base, and then the flexible circuit board and the buckle cover are placed in turn. After accurate positioning, the flexible circuit board and the magnetic jig are taken out from the positioning base together for solder paste printing, patch and reflow soldering processes.

Since the furnace jig needs to be frequently placed in high temperature, the magnet needs to use high-temperature resistant Samarium Cobalt magnets. Samarium Cobalt magnet has become the best choice for magnetic furnace jigs in SMT due to its excellent high-temperature resistance.